Location: Homepage > News > Company news

Company news

What are the categories of automotive models?

Source: | Date:

2018-02-21

| Hits:

Keywords: What are the categories of automotive models?

There are many methods for classifying automotive plastic molds, and they can be divided into the following categories according to the different methods of molding and processing plastic parts:

Injection mould

Injection mold is also called injection mold. The molding process of this mold is characterized in that the plastic raw material is placed in the heating cylinder of the injection machine. The plastic is melted by heat and pushed by the screw or plunger of the injection machine. The injection system of the nozzle and the mold enters the cavity of the mold. The plastic is maintained in the mold cavity by heat preservation, pressure keeping, cooling and solidification. Because the heating and pressurizing device can play a role in stages, injection molding can not only form plastic parts with complicated shapes, but also has high production efficiency and good quality. Therefore, injection molding occupies a large proportion in the molding of plastic parts, and the injection mold occupies more than half of the plastic molding dies. Injection molding machines are mainly used for the molding of thermoplastics, and in recent years, they have gradually been used for molding thermosetting plastics.

Compression mold

Compression die is also known as a compression die or a pressure die. The molding process of the mold is characterized in that the plastic raw material is directly added into the open mold cavity, and then the mold is closed. After the plastic is in a molten state under the action of heat and pressure, the cavity is filled with a certain pressure. At this point, the molecular structure of the plastic produced a chemical cross-linking reaction that gradually hardened and shaped. Compression molds are mostly used for thermosetting plastics, and their molded plastic parts are mostly used for the housing of electronic switches and daily-use products.

Transfer mode

Transfer molds are also called injection molds or extrusion molds. The molding process of this mold is characterized in that the plastic raw material is added into the preheating feed chamber, and then the pressure is applied to the plastic raw material in the feed chamber by the press column. The plastic is melted under high temperature and high pressure and enters the cavity through the mold's pouring system, and then Chemical crosslinking reaction gradually solidifies. The transfer molding process is mostly used for thermosetting plastics and can form plastic parts with relatively complex shapes.

Extrusion die

Extrusion die, also known as extrusion head. This mold can continuously produce plastics with the same cross-sectional shape, such as plastic pipes, bars, sheets, and the like. The heating and pressurizing device of the extruder is the same as the device of the injection machine. The plastic in the molten state will form continuous and continuous plastic parts through the head, and the production efficiency is particularly high.

In addition to the above-listed types of plastic molds, there are vacuum forming molds, compressed air molds, blow molds, and low-foaming plastic molds.

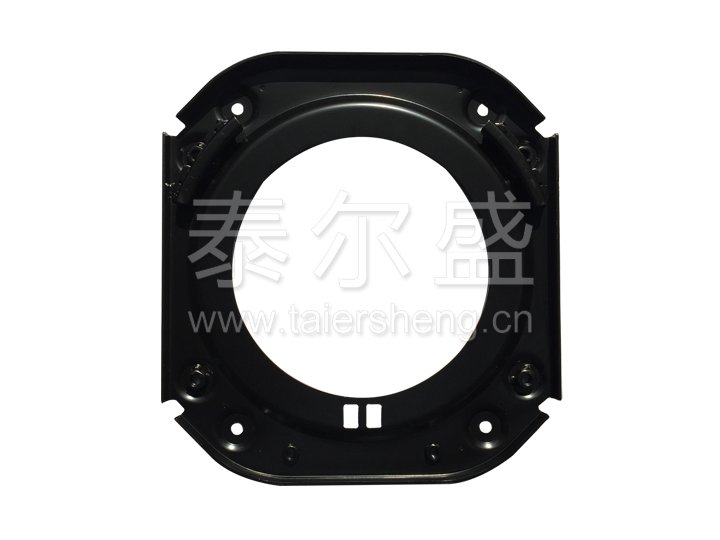

Stampings on automotive bodies are generally divided into cover parts, beam members and general stamping parts. The stampings that can clearly indicate the characteristics of the car image are car covers. Therefore, the more specific car mold can be said to be "car cover stamping mold." Referred to as car cover die. For example, the trimming die of the front door outer panel, the punching die of the front door inner panel, and the like.

Injection mould

Injection mold is also called injection mold. The molding process of this mold is characterized in that the plastic raw material is placed in the heating cylinder of the injection machine. The plastic is melted by heat and pushed by the screw or plunger of the injection machine. The injection system of the nozzle and the mold enters the cavity of the mold. The plastic is maintained in the mold cavity by heat preservation, pressure keeping, cooling and solidification. Because the heating and pressurizing device can play a role in stages, injection molding can not only form plastic parts with complicated shapes, but also has high production efficiency and good quality. Therefore, injection molding occupies a large proportion in the molding of plastic parts, and the injection mold occupies more than half of the plastic molding dies. Injection molding machines are mainly used for the molding of thermoplastics, and in recent years, they have gradually been used for molding thermosetting plastics.

Compression mold

Compression die is also known as a compression die or a pressure die. The molding process of the mold is characterized in that the plastic raw material is directly added into the open mold cavity, and then the mold is closed. After the plastic is in a molten state under the action of heat and pressure, the cavity is filled with a certain pressure. At this point, the molecular structure of the plastic produced a chemical cross-linking reaction that gradually hardened and shaped. Compression molds are mostly used for thermosetting plastics, and their molded plastic parts are mostly used for the housing of electronic switches and daily-use products.

Transfer mode

Transfer molds are also called injection molds or extrusion molds. The molding process of this mold is characterized in that the plastic raw material is added into the preheating feed chamber, and then the pressure is applied to the plastic raw material in the feed chamber by the press column. The plastic is melted under high temperature and high pressure and enters the cavity through the mold's pouring system, and then Chemical crosslinking reaction gradually solidifies. The transfer molding process is mostly used for thermosetting plastics and can form plastic parts with relatively complex shapes.

Extrusion die

Extrusion die, also known as extrusion head. This mold can continuously produce plastics with the same cross-sectional shape, such as plastic pipes, bars, sheets, and the like. The heating and pressurizing device of the extruder is the same as the device of the injection machine. The plastic in the molten state will form continuous and continuous plastic parts through the head, and the production efficiency is particularly high.

In addition to the above-listed types of plastic molds, there are vacuum forming molds, compressed air molds, blow molds, and low-foaming plastic molds.

Stampings on automotive bodies are generally divided into cover parts, beam members and general stamping parts. The stampings that can clearly indicate the characteristics of the car image are car covers. Therefore, the more specific car mold can be said to be "car cover stamping mold." Referred to as car cover die. For example, the trimming die of the front door outer panel, the punching die of the front door inner panel, and the like.

Next: Null

News

- 2018-03-27 > What is the overall process of mold design and manufacturing?

- 2018-03-27 > Will the seat frame have welding standards?

- 2018-03-27 > What is the production process of the car seat frame?

- 2018-03-27 > Can the car front cushion recliner be repaired?

- 2018-03-27 > Does the difference in the level of flatness in the car seat affect the slide?

- 2018-03-27 > CNC machine tool is the key to automotive mold

- 2018-03-20 > Automotive mold high-speed cutting technology

- 2018-02-21 > What are the categories of automotive models?

- 2018-02-08 > Nine trends in the development of the automotive mold industry

- 2018-01-05 > 2018 China Car Seat Market Research and Development Trend Forecast Report

Products